1966 mustang sheet metal thickness The "better" quality repo panels are listed as being 19ga. I believe it's from a conversion to standard gauge from a metric measurement of the metal thickness. Most of the . You'll need such a faceplate for this, as well as a right-angled ½" FMC connector to accept the flex conduit whip on your oven, a set of 4 Ilsco MAC-618 MAC-Block™ connectors as the wires from the wall appear to be aluminum(!), a short length of 10AWG bare solid copper for use as a box grounding pigtail, and a 10-32 green grounding screw.

0 · what gauge sheet metal mustang

1 · vintage mustang thickness

2 · vintage mustang sheet metal gauge

3 · vintage mustang gauge replacement

4 · vintage mustang 4x4 sheet metal

5 · thickness of sheet metal mustang

6 · thickness of sheet metal

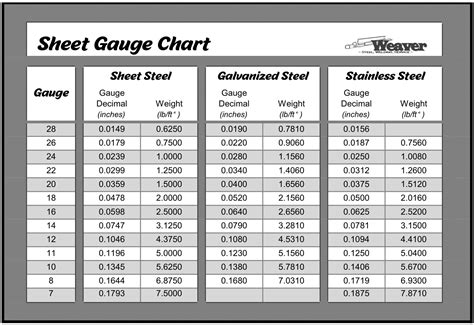

7 · 18 gauge sheet metal thickness

Tatago 18 Inch (H) Heavy Duty Full Metal Bed Frame, 3500 lbs Capacity Metal Platform Bed frames Full Size, Sturdy Steel Mattress Foundation with Storage, Non-Slip, No Noise No Box .

what gauge sheet metal mustang

The sheet metal up by the front grill and by the trunk lip measures at 0.050" on my car. That puts it at 18 gauge both sides painted. The circular opening under the trunk were 0.041" or 19 gauge, both sides painted. I just welded on my emergency brake brackets, they were 14 .The "better" quality repo panels are listed as being 19ga. I believe it's from a .

vintage mustang thickness

Does anyone know what the original metal gauge (thickness) was from Ford for the .

The "better" quality repo panels are listed as being 19ga. I believe it's from a conversion to standard gauge from a metric measurement of the metal thickness. Most of the .

The older cars usually used 20 gauge (.036 inch) sheet for skin. Newer cars,21 gauge (.033 inch) and 22 gauge (.030 inch) or even thinner. You may find 14 gauge (.075 .

Does anyone know what the original metal gauge (thickness) was from Ford for the body panels (doors, fenders, quarters etc)? I need to weld in small flat patch panels and want .

While making parts for Ford, back before they changed the pickup body styles in the 90's, the sheet metal thickness in a F-150 was thinner than material used in the F-250. Only a . Thin sheet metal to 1/4-3/8 is no problem. Heat adjustments are fine but like it was said before you gotta get the wire speed to work properly or you're gonna have nothing but .

Off the shelf subframe connectors are using ~1/16 thick, these are 1/8. The rear torque boxes have been eliminated and replaced with a 2X4 crossmember. The front torque .

vintage mustang sheet metal gauge

Just for posterity, if anyone reads this, here is the order I found that worked. hang fenders and get door gap correct. Tighten upper rear and bottom bolts but leave others loose. . Here's One Way To Re-Skin A Pony With New Dynacorn Sheetmetal. Classic Mustangs are notorious for their short-deck, long-nose styling. Unfortunately, their voluptuous hips are vulnerable to just. We may earn a commission for products purchased through links on this page The sheet metal up by the front grill and by the trunk lip measures at 0.050" on my car. That puts it at 18 gauge both sides painted. The circular opening under the trunk were 0.041" or 19 gauge, both sides painted. I just welded on my .

The "better" quality repo panels are listed as being 19ga. I believe it's from a conversion to standard gauge from a metric measurement of the metal thickness. Most of the original panels are actually 18ga. I checked with a local metal supplier and a welding shop for some sheet steel. The older cars usually used 20 gauge (.036 inch) sheet for skin. Newer cars,21 gauge (.033 inch) and 22 gauge (.030 inch) or even thinner. You may find 14 gauge (.075 inch) could be used for fabricating internal reinforcements, but it's too thick for skin. Does anyone know what the original metal gauge (thickness) was from Ford for the body panels (doors, fenders, quarters etc)? I need to weld in small flat patch panels and want to use the correct thickness to match. I'm specifically referring to 69-70 model years. Thanks!!

While making parts for Ford, back before they changed the pickup body styles in the 90's, the sheet metal thickness in a F-150 was thinner than material used in the F-250. Only a few thousandths of an inch but thicker.

Thin sheet metal to 1/4-3/8 is no problem. Heat adjustments are fine but like it was said before you gotta get the wire speed to work properly or you're gonna have nothing but trouble. For what it's worth.

Off the shelf subframe connectors are using ~1/16 thick, these are 1/8. The rear torque boxes have been eliminated and replaced with a 2X4 crossmember. The front torque boxes will also be eliminated and replaced with 2X4 box. Just for posterity, if anyone reads this, here is the order I found that worked. hang fenders and get door gap correct. Tighten upper rear and bottom bolts but leave others loose. Put the grille and headlight buckets on, leaving the headlight buckets loose. Install the stone guard. Tighten the headlight buckets, fenders, and stone guard bolts. Here's One Way To Re-Skin A Pony With New Dynacorn Sheetmetal. Classic Mustangs are notorious for their short-deck, long-nose styling. Unfortunately, their voluptuous hips are vulnerable to just. We may earn a commission for products purchased through links on this page

The sheet metal up by the front grill and by the trunk lip measures at 0.050" on my car. That puts it at 18 gauge both sides painted. The circular opening under the trunk were 0.041" or 19 gauge, both sides painted. I just welded on my . The "better" quality repo panels are listed as being 19ga. I believe it's from a conversion to standard gauge from a metric measurement of the metal thickness. Most of the original panels are actually 18ga. I checked with a local metal supplier and a welding shop for some sheet steel.

The older cars usually used 20 gauge (.036 inch) sheet for skin. Newer cars,21 gauge (.033 inch) and 22 gauge (.030 inch) or even thinner. You may find 14 gauge (.075 inch) could be used for fabricating internal reinforcements, but it's too thick for skin. Does anyone know what the original metal gauge (thickness) was from Ford for the body panels (doors, fenders, quarters etc)? I need to weld in small flat patch panels and want to use the correct thickness to match. I'm specifically referring to 69-70 model years. Thanks!! While making parts for Ford, back before they changed the pickup body styles in the 90's, the sheet metal thickness in a F-150 was thinner than material used in the F-250. Only a few thousandths of an inch but thicker. Thin sheet metal to 1/4-3/8 is no problem. Heat adjustments are fine but like it was said before you gotta get the wire speed to work properly or you're gonna have nothing but trouble. For what it's worth.

precision cnc machining st. charles mo

Off the shelf subframe connectors are using ~1/16 thick, these are 1/8. The rear torque boxes have been eliminated and replaced with a 2X4 crossmember. The front torque boxes will also be eliminated and replaced with 2X4 box.

Just for posterity, if anyone reads this, here is the order I found that worked. hang fenders and get door gap correct. Tighten upper rear and bottom bolts but leave others loose. Put the grille and headlight buckets on, leaving the headlight buckets loose. Install the stone guard. Tighten the headlight buckets, fenders, and stone guard bolts. Here's One Way To Re-Skin A Pony With New Dynacorn Sheetmetal. Classic Mustangs are notorious for their short-deck, long-nose styling. Unfortunately, their voluptuous hips are vulnerable to just.

vintage mustang gauge replacement

vintage mustang 4x4 sheet metal

thickness of sheet metal mustang

Our wall mount enclosures are designed to provide reliable protection for your electrical and electronic components. We offer various sizes, materials, and configurations to suit your specific application requirements.

1966 mustang sheet metal thickness|thickness of sheet metal